Customer: DZSP21

Location: Route 16

Start: October 2010

Complete: May 2012

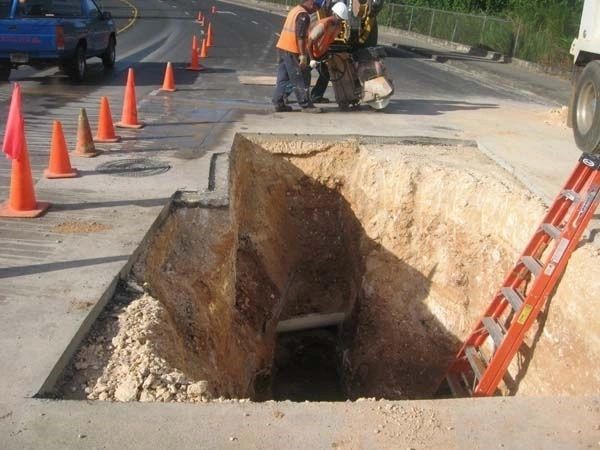

Scope of Work: Provide stamped design drawings for new waterline installation. Obtain road closure permit from DPW. Obtain underground utility clearances. Mobilize personnel, equipment and materials to jobsite. Set up all required road closure signs, cones, concrete barriers to close middle and outer lanes, redirect traffic to inner and center lanes using cones. Saw cut and remove asphalt pavement. Begin excavation near location of end of concrete encasement at the bottom of the hill, approximately 6 feet deep, and will extend uphill approximately 600 LF to end of concrete encasement; daily production is projected at 80-100 LF per day.

Excavated material to be loaded directly into dump trucks and transported to stockpile site; front end loader to be stationed at stockpile site to load dump trucks for daily trench backfilling operations. Install trench shoring into trench prior to any personnel entering. Install 12” C-900 water pipe into trench, cover with bedding sand, minimum 6 inch cover on all sides, pipe joints to be left exposed; the open end of first pipe will be covered with restrained joint blind flange; hydrostatic testing of installed pipe to be completed each daily. Pipe to be fully covered with bedding sand, backfilled and compacted, minimum 3 feet of flowable fill installed. Cover backfilled trench with steel plates, edges to be beveled with cold mix asphalt

Once pipe installation has reached the end of the concrete encased pipe, disinfect pipe run with 200ppm chlorine solution and perform BacT testing. Excavate and expose un-encased ACP pipe at each end of encasement, approximately 12 feet deep, install trench shoring; hazardous materials subcontractor to cut and remove 4 foot section of ACP from each end. Install restrained joint 45 degree elbows to cut ends of ACP with section of C-900 running up at 45 degree angle to level of new C-900, install restrained joint elbows and connect to new C-900; coordinate for isolation valves to be opened to restore water service. Asphalt paving subcontractor to mill asphalt to existing base coarse and will re-compact base, apply asphalt primer and install 3” thick hot mix asphalt pavement with ¾” friction course layer on top. Lane striping, markers and reflectors to be restored.